MANN GCA DSW 4800 Wafer Stepper

Additional figures are at the end of this article.

Safety

-

The system employs a high pressure mercury lamp. If a catastrophic failure

of the lamp should occur, avoid touching glass debris or inhaling mercury

vapor fumes. Notify a staff member at once.

-

The UV light produced by the lamp can cause erythema of the skin (similar

to sunburn), conjunctivitis and possible retinal burn that could result

in blindness. Though the operator is protected from direct exposure to

UV light it is recommended that the operator does not look at the mask/wafer

assembly at the time of the exposure; indirect UV light may also harm the

eye retina.

-

The system employs infrared lasers for stage and focus control. The operator

should avoid placing any parts of the body in the path of the laser beam.

Environmental Enclosure

The environmental enclosure provides the thermal stabilization necessary

for the stepper to achieve and maintain precision alignment and focus.

The doors to the chamber should always be kept closed, except as is necessary

during performance of an alignment.

Direct Step on Wafer (DSW) System and Automatic Wafer Handler (AWH)

The DSW System comprises the complete step and repeat microlithography

hardware and software. A subsystem of the DSW, the AWH, controls wafer

handling and alignment. The LPS AWH hardware supports only the manual wafer

handling and alignment modes of the AWH.

Keyboard Commands and Controls

Note: Keyboard input is case-sensitive.

-

COPY

-

Copies a job file from another user's directory to the current user's directory.

Follow prompts for specifying file input/output source/destination locations/names.

-

DELETE

-

Deletes a job file from the current user's directory. Follow prompts for

specifying the file to be deleted.

-

EDIT

EDIT

-

Edits a previously specified job file.

-

EXEC

EXEC

-

Executes a previously specified job file.

-

EXPO

EXPO

-

Initiates an exposure/focus test of a previously specified job file..

-

LISTF

-

Displays current user's files.

-

LOAD

-

Moves the stages to the wafer loading position.

-

LOG IN and LOG OUT

-

Controls access to the AWH.

-

"LOG IN $ZZ$DX1"

-

ZZ = your login name

-

DX1 = disk drive

-

"LOG OUT"

-

OPER

-

Sets the default joysticks speed rates for the current user.

-

ORIG

-

Retunes the laser positioning system for the stages.

-

PFCORG

-

Retunes the column focus to the calibrated 251 focus benchmark.

-

RENAME

-

Renames a current user's file. Follow prompts for specifying input/output

filenames.

-

SPEC

SPEC

-

Creates a new job specification file.

-

ALT+F1

-

Returns stepper software to setup/config. mode from command mode.

-

CTRL-A

-

Toggles view on TV display between right and left alignment scopes.

-

CTRL-D

-

Enables a jog mode for joystick during wafer alignment. Stages move one

stepping distance in the selected direction.

-

CTRL-E

-

Cancels jog mode (CTRL-D).

-

CTRL-F

-

Enables a user to search for wafer alignment keys. Each issue of CTRL-F

causes stages to move a step at a time along an expanding rectangular spiral.

-

CTRL-O

-

Allows a user to temporarily modify wafer alignment joystick rates.

-

CTRL-P

-

Initiates a progress report while a pass is being executed.

-

CTRL-Q

-

Aborts the alignment/exposure.

-

CTRL-S

-

Halts the scrolling of the video terminal display.

-

CTRL-Z

-

Suspends system activity until a second CTRL-Z is issued.

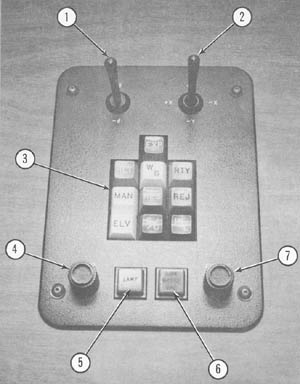

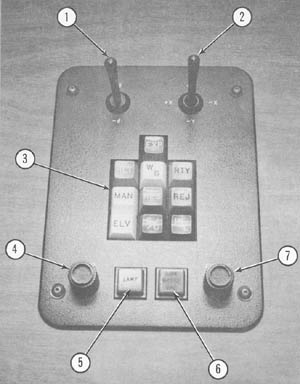

Button Box Controls

The button box controls, which are in front of the TV monitor, operate

the manual mode of the Automatic Wafer Handler. Some of the buttons are

for the automatic mode, which is not installed at LPS.

-

X-Y Joystick

-

Controls the X-Y stages during wafer alignment. It has dual speeds: (1)

Fine motion when the joystick is moved slightly, and (2) coarse motion

when the joystick is moved beyond the click. Align X-Y with the right-side

fidicials only.

-

THETA Joystick

-

Rotates a wafer about its theta axis during wafer alignment. As with the

X-Y joystick, it has dual speeds. Align theta with the left-side fiducials

only.

-

EXP (EXPOSE)

-

After alignment is completed, press EXPOSE to expose the wafer.

-

HLT (HALT)

-

Stops the AWH without stopping the exposure pass in progess. Cancel with

the S/C button.

-

W/S (WAFER SCALE)

-

Adjusts the stepping matrix dimension at each level for precise overlay

of all levels by verifying the position of, and making scale corrections

for, the left (theta) alignment mark in the x-axis direction. Need

for such scaling can result from changes to the wafer dimensions during

processing across levels, or from dimensional error in reticle fiducial

placement. W/S is pressed after normal fine alignment by aligning the left

(theta) alignment mark in the x-axis only. Do not re-align the x-y (right)

alignment mark, nor the left (theta) alignment mark in the theta direction.

Then press EXP.

-

RTY (RETRY)

-

Not applicable to manual alignment.

-

MAN (MANUAL)

-

Initiates manual alignment mode.

-

RES (RESET)

-

Stops the Automatic Wafer Handler immediately. Run cannot be resumed.

-

REJ (REJECT)

-

Not applicable for manual alignment.

-

ELV (ELEVATE)

-

Not applicable for manual alignment.

-

S/C (START/CONTINUE)

-

Initiates the Automatic Wafer Handler at the start of a run. Resumes operation

after the HALT button has been pressed or an "AWH Time Out" has occurred.

-

1st L (FIRST LAYER START)

-

Not applicable for manual alignment.

-

LAMP Intensity Control Knob

-

Controls the intensity of the wafer illuminator.

-

LAMP ON/OFF Pushbutton

-

Turns on or off the wafer illuminator.

-

LOW WAFER VAC Warning Light

-

Warns a user that the wafer chuck's vacuum level is too low.

-

FOCUS knob

-

Adjusts the focus of the wafer alignment keys on the TV monitor.

|

1. Theta Joystick.

2. X-Y Joystick.

3. AWH Control Buttons.

4. Lamp Intensity Control.

5. Lamp On/Off.

6. Low Wafer Vac Warning Lamp.

7. Focus Control. |

Notes

The digital Focus Meter indicates position, not motion. Zero corressponds

to the calibrated benchmark focus of 251 where 1 unit = 0.25 um.

The digital Theta Movement Meter indicates motion, not position.