Hydrogen-terminated Silicon Surface Devices |

|

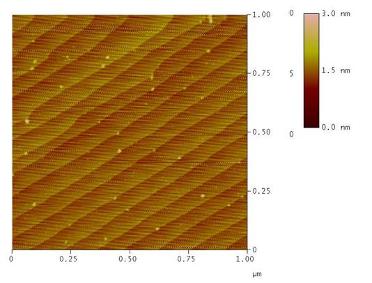

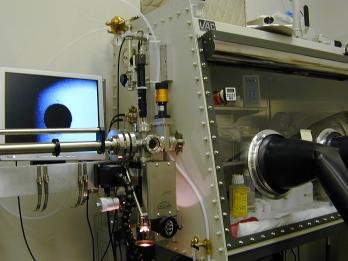

Chemical surface preparation methods The key to preparing atomically flat hydrogen terminated (or passivated) silicon [111] surfaces is to etch them in high pH fluoride solutions (such as NH4F) that contain minimal dissolved oxygen. Our surfaces are currently prepared in a glovebox containing less than 1 ppm O2. All solutions are allowed to equilibrate in this atmosphere prior to sample etching. Our bonding apparatus (mounted on the left side of the glovebox in the picture to the right) enables cm sized silicon chips to be bonded in vacuum immediately after surface preparation. Surfaces can be characterized in our laboratory by atomic force microscopy and by contactless measurement of surface conductance and minority carrier lifetime. Samples prepared in an inert environment and sealed in glass vials have long minority carrier lifetimes that do not diminish appreciably for several days. Pictures show our glovebox apparatus, an AFM image of a treated Si:H [111] surface on which atomic steps are visible, and our induction coil for contactless conductance and minority carrier lifetime measurements. A 12.5x25.0 mm2 Si chip is visible in a sealed glass vial in the foreground. |

|

Silicon-based quantum computing home page B. E. Kane November, 2010 |