Product Testing

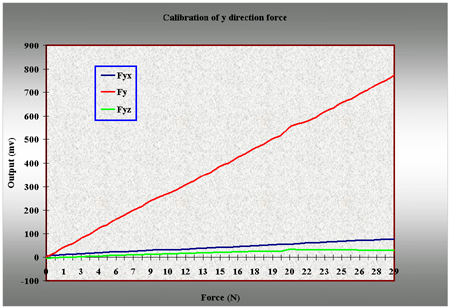

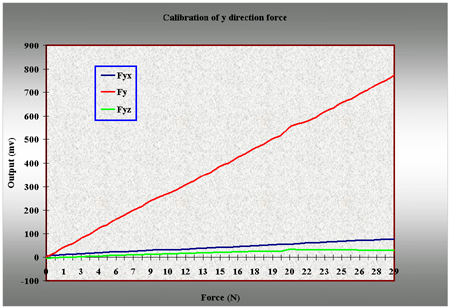

To insure that the design had the sensitivity necessary to be able to measure the force during the drilling process, the device was tested for a number of different loading conditions. The device was tested with weight ranging being 0 and 30 N in all three directions. For each of the loading conditions the voltage measurements were taken for each component of the force. The reason for taking the measurements at all three components is to measure the cross talk of the device. If the device were to operate perfectly, each of the gauges would only read values for their respective force. Unfortunately due to errors in the manufacturing process and the overall design of the dynamometer, each gauge tends to read some values for off axial force. In fact, the measure of an excellent dynamometer is a device that minimizes the amount of cross talk between the different strain gauges. The result for this dynamometer proved to be very encouraging. For each of the force measurements there was a minimal amount of cross talk between the different components. For the X and Y components of the force there were only small reading by the Z gauges. While the cross talk was more prevalent in the

Z direction, the overall results show only reasonable amounts of cross talk. In addition to the reasonable amount of cross talk there is another important design aspect of force dynamometer. This is the fact that the relation ship between the force and the voltage needs to be a linear relationship. The reason the relationship needs to be linear is so that the operator can easily correlate the voltage to the force. If the relationship were not linear then the operator would have to interpolate the value of force for every voltage which would be very time consuming. However, if the relationship between the voltage and force is linear than the operator can calculate the force by multiplying the voltage by a constant. It is this constant that is solved for in the calibration procedure.

Results from Calibration