Dental research, like engineering, has generated a need for a

large assortment of test instrumentation. Often, engineers and

dentists collaborate to design systems that combine the mechanisms

of machining with the operations of dentistry. The goal is to

improve analysis of dental operations to raise existing technology

and develop new ones. Specifically, research in areas of material

science and tooth wear shows a significant demand for an accurate

method of modeling human jaw motion. Though computer modeling

is an accurate method of complex motion simulation, systems like

the human jaw with known physical geometry and measurable variables

can be more accurately modeled using tangible artifacts. It is

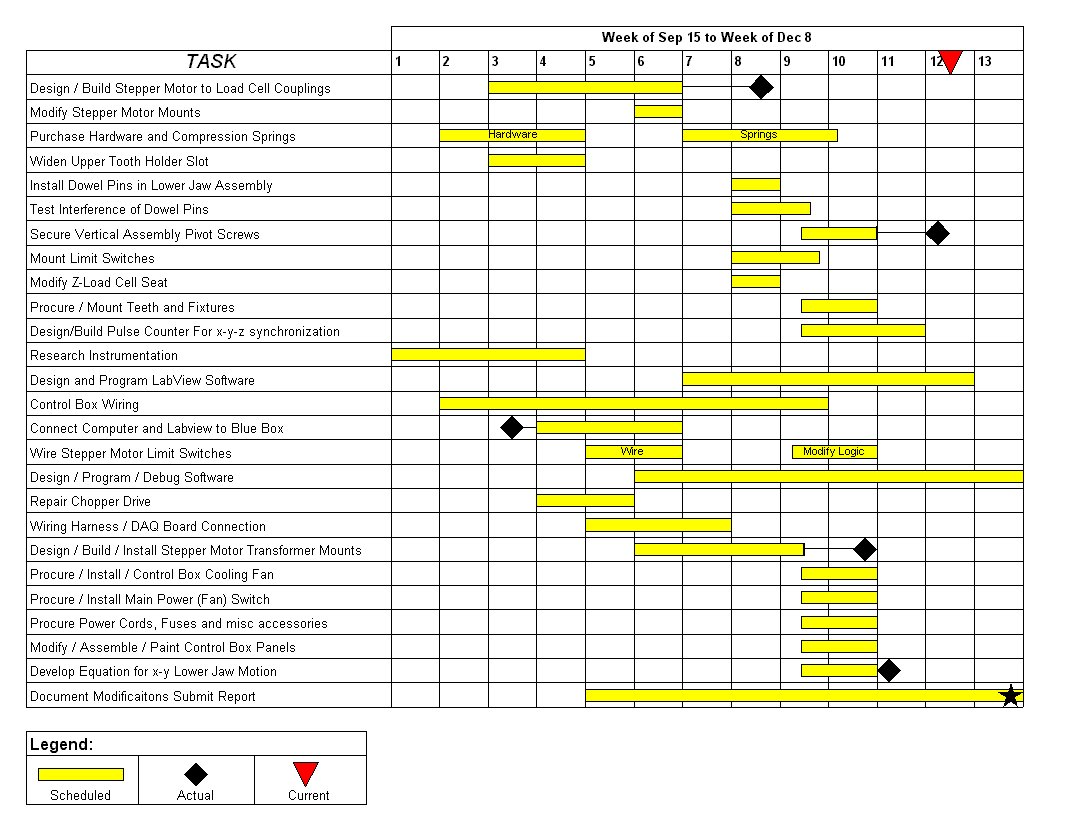

the intent of this team to assemble and modify a mouth motion

simulator designed by a group of ENME 414 students in the spring

of 1997. The original design is discussed in the referenced report

and the improvements and design methodology are discussed below.

Human chewing requires the complex, coupled motion of two sets of jaws. The upper jaw is relatively stationary, acting as a reference plane, and the lower jaw lifts towards it and shifts laterally as the two jaws come together. The intent of the mouth motion simulator project is to:

- Model motion in the three principal directions

- Accurately simulate the chewing cycle during tooth contact

- Synchronize vertical and horizontal motions through electro-mechanical control

- Generate and measure forces in the three principal directions.

* See Gedion, Lee, Ou, Rebeck, Shaiou, and Yen, "Mouth Motion Simulator", Dept of Mechanical Engineering: 1997. for further details about the original design. ** Final Design Drawing By Erik Rebeck.