University of Maryland

University of Maryland

ENME 414

Spring

2000

Team 3 –

Members

Steve Hedgespeth

Dean Menegay

Melissa Kay Norton

Omoefe Ozomoro

Vu Phung

Angel Prado-Gonzalez

Instructor

Design Verification of a Medical Device through Construction

Overview:

In the process of product development, design engineers prepare drawings first, then manufacture parts or purchase parts, assemble the components, and finally test the assembled products. A medical device used for material characterization and performance evaluation has been designed. There is a current prototype and a second prototype is in the process of being built. The engineering drawings need verification, both components and assemblies.

Methodology:

To accurately produce the components and assemblies, Team 3 used redundancy in measurements and in CAD drawings. Paired members took measurements and constructed basic components of the medical device housing. Drawings were then compared to check accuracy and clarity of the drawings. The components were subsequently assembled. All holes and edges where checked to verify proper alignment.

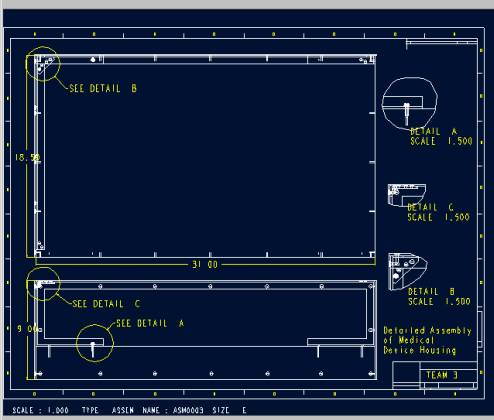

Once the components and assemblies were checked, they were printed on a 34 x 44 inch plotter. A plotter was used to show the components and how they were assembled with greater accuracy. In addition, the plots can be used on the shop floor to machinist a feel of how big the component is and to verify NC machine test runs. Below are examples of the completed drawings.

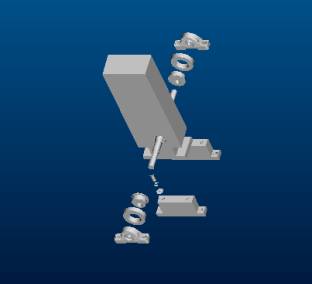

Figure 1: Exploded State of Medical Device Housing

Figure 2: Unexploded State of Medical Device with 3 Details of Critical Joints

Figure 3: Exploded State of Medical Device Structure

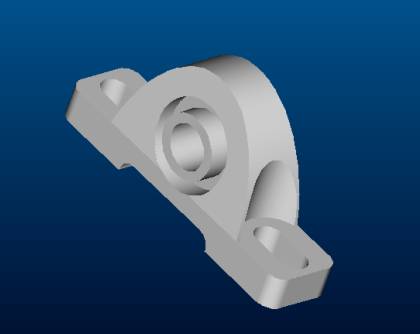

Figure 4: Part 3 of Medical Device Structure

Conclusions:

Initially Team 3 was confident in its ability to complete this project, however we came across several obstacles. First, when measuring the component, each team member chose different reference points which caused inconsistencies when assembling the components. Second, the accuracy of the measurements was compromised because there was not proper equipment available to complete the measurements. Finally, having six members in our group greatly restricted the times we could meet and discuss our findings and concerns. A possible improvement would be to reduce the group size by increasing the number of teams and projects.

A special thanks goes out the teaching assistants and graduate students that helped our team put together this project.