Team 5

Progress Report

(April 7, '97)

Introduction

Since Team five's last progress report, the group has

been to the Smithsonian on five occasions. Fortunately, two graduate students

(Yi Chien and Li Xun) are working in this area and have offered their assistance.

Initially, a tutorial guide was given to each member of the group and was

subsequently reviewed prior to the first scan. The team is currently in

the process of editing a 3D-digitized scan file using the program Datasculpt.

The following paragraphs will briefly discuss the methodology used in understanding

the 3D-Digitizer (Laser Design Model #3000, see Figure 1 "Huxley"),

scanning editor (Datasculpt), and future goals.

Fig. 1 Laser Design Model #3000, "Huxley"

Fig. 1 Laser Design Model #3000, "Huxley"

Application of the 3D-Digitizer

(Laser Design Model #3000)

Digitization is the inverse of

computer aided manufacturing (CAM) and allows the creation of a computerized

representation. In this case, the specimen used was a lag bolt. The laser

scanner operates on the same basis as the computer numerical control (CNC)

machine. For example, the bed of the scanner moves the specimen, in the

X-Y-Z directions, in the same fashion as the CNC machine. In addition,

the laser scanner also includes a rotational feature (A-axis).

Initially, the team did an introductory

scan for a learning experience. During the scan, the group learned how

to set up the initial parameters on the computer that operates the laser

scanner. These parameters define the limits of the Òlag boltÓ

scan. These limits produce a Òscanning windowÓ on the computer,

which enables the operator to view the scanning process. The two types

of scanning processes are ÒrotationalÓ and Òflat.Ó

The rotational scan allows the operator to scan the specimen in the X-Z-A

directions. The X-Y-Z directions are used for the flat scan. For project

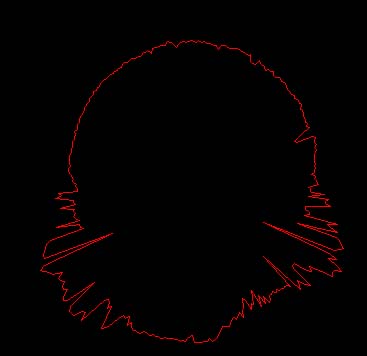

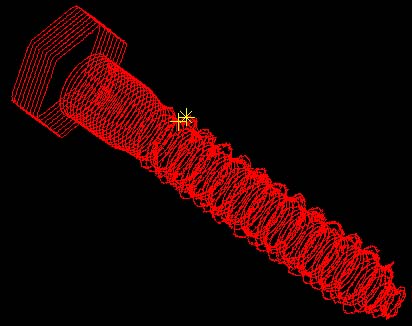

five, the group performed a rotational scan (see Figure 2 Front) for the

length of the lag bolt and a flat scan on the cap.

Fig 2. Front View of Scanned Image

Fig 2. Front View of Scanned Image

Scanning Editor

(Datasculpt)

Datasculpt is the tool used for

the process of editing a scanned file (.SCN). The program allows the editor

to view the scanned object in all of the orthogonal and isometric views.

One of the previously mentioned limits of the scanning process includes

Òline density.Ó This limit defines the distance between each

line scanned on the object. Once in Datasculpt, each line is known as a

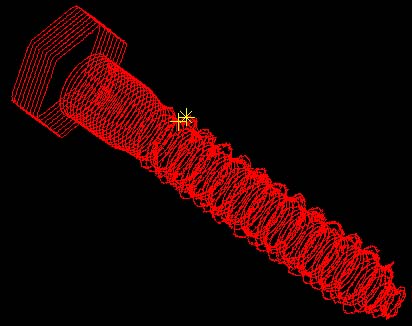

clip, which must be edited individually (see Figure 3Clip). Upon completion

of the editing process, Datasculpt is then used for meshing the clips together

to create a 3D surface model.

Fig. 3 A single clip of the scanned data (in area of the threads)

Unfortunately, the scanning process

is not error proof. For example, object placement, surface texture, the

laser beam traversing beyond the boundary of the object, and the luster

of the object, all contribute to errors. Therefore, the focus of Datasculpt

is to mitigate, or alleviate the errors, and then manipulate the scanned

lines into a 3D surface model, for which a CAD/CAM system will recognize.

Figure 4 shows a partially edited lag bolt, from the cap up to the yellow

star. It took six hours to scan the length of the lag bolt and eight hours

to edit this small section.

Fig. 3 A single clip of the scanned data (in area of the threads)

Unfortunately, the scanning process

is not error proof. For example, object placement, surface texture, the

laser beam traversing beyond the boundary of the object, and the luster

of the object, all contribute to errors. Therefore, the focus of Datasculpt

is to mitigate, or alleviate the errors, and then manipulate the scanned

lines into a 3D surface model, for which a CAD/CAM system will recognize.

Figure 4 shows a partially edited lag bolt, from the cap up to the yellow

star. It took six hours to scan the length of the lag bolt and eight hours

to edit this small section.

Fig. 4 Isometric view of scanned data

Fig. 4 Isometric view of scanned data

Future Goals of the Team

In the remaining weeks of class,

the group still has three goals to accomplish. First and foremost, the

editing/meshing process for the scanned lag bolt has to be completed. The

work completed thus far, on the digitizer and Datasculpt, has been done

under the advise and guidance of Yi Chien. Yi Chien, having written a thesis

paper on 3D-Digitization, has proven to be a valuable resource to the group.

Secondly, integration of the meshed

file into ProEngineer will probably be the most difficult to achieve, because

of the size of the data files and current drawing programs are unable to

handle these large files. Currently data is able to be transformed into

an STL file for stereolithography, enabling a three dimensional prototype

to be created. Goals involve utilizing Pro/Engineer software to accomplish

this task. An interface routine needs to be created in order to convert

the data from the digitizer output format to that of Pro/Engineer (.IBL)

files.

Finally, creation of the 3D Prototype,

using the transformed data from the lag bolt scanning, will complete the

project. Whether this will be done using either the CNC or STL machine

is uncertain at this time.

Back to Project 5 Homepage

![]()

![]()

![]()